How Lathe Soft Jaws Improve Accuracy and Surface Finish

Learn how lathe soft jaws improve accuracy and surface finish in machining. Discover their benefits, use cases, and expert tips for better results in turning operations.

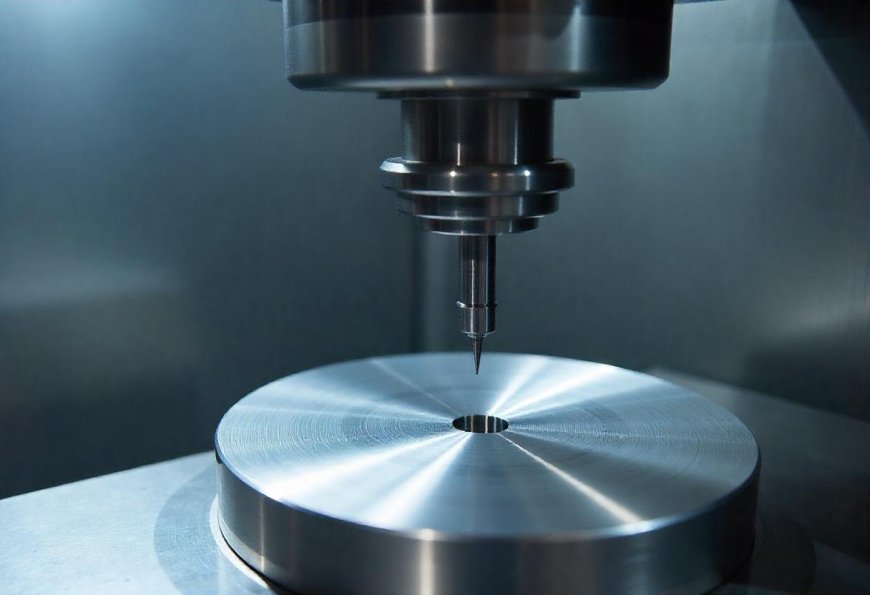

Lathe soft jaws are important tools used in many machine shops. They help you hold parts tightly during turning without damaging them. These jaws are soft, easy to shape, and perfect for gripping delicate or odd-shaped pieces. Using lathe soft jaws can improve your machining accuracy and give your parts a much better surface finish. In this blog, well explain how soft jaws work, why they are useful, and how they can help you make better products.

What Are Soft Jaws and How Do They Work?

Definition and Purpose

Soft jaws are special jaws used with lathe chucks. Unlike hard jaws, soft jaws are made from soft metals and are easy to shape. Their main purpose is to hold parts tightly during machining. Since they are soft, they dont damage or scratch the parts surface. This is very helpful when working with finished or delicate materials.

Material and Manufacturing

Most lathe soft jaws are made from materials like aluminum, mild steel, or brass. These metals are softer than the part being machined. Because they are soft, you can easily machine or mill them to fit the shape of the part you want to hold. Many shops use CNC machines to cut soft jaws so they fit the workpiece exactly. This ensures a perfect grip and keeps the part from moving during turning.

Setups and Use Cases

Soft jaws are very helpful when working with odd-shaped, delicate, or thin-walled parts. If you use hard jaws for such pieces, they may slip or get damaged. Soft jaws can also be used again and again if they are properly cared for. You can also change setups quickly, saving time during part changeovers. Thats why they are common in both small shops and high-volume production centers.

Improved Accuracy with Soft Jaws

Precise Positioning and Clamping

One big benefit of lathe soft jaws is that they allow precise positioning of the workpiece. Since they are shaped to fit the part, the piece always sits in the same position. This reduces runout or small movements that can cause errors.

Example: One company saw a 50% drop in part deviation after switching from standard jaws to custom soft jaws. That means their parts were more accurate and needed less fixing later.

Minimized Part Distortion

Because soft jaws are made from softer material, they spread out the pressure more evenly. Hard jaws press in small areas, which can bend or warp the part. Soft jaws grip the full surface, so the part stays straight and strong during turning.

Expert tip: One machinist said, Soft jaws minimize part shifts, ensuring specs are met.

This is very important if you're working with thin metal parts or parts with small details that need to stay in shape.

Tolerance Reproduction

In machining, tolerance means how close your part is to the exact size it should be. With soft jaws, you can hold the part in the same way every time. This helps you make many pieces with the same size and shape, which is very useful in high-volume jobs.

Better Surface Finish Achieved

Reduced Vibrations and Chatter

When a part is not held tightly, it can shake or vibrate while cutting. This is called chatter, and it makes the surface rough. Soft jaws hold the part firmly, reducing vibrations. This gives you a smooth surface on your finished part.

Data Point: Studies show that using soft jaws can improve surface finish by 2030%. That means youll spend less time polishing or finishing parts later.

Less Damage to Workpiece Surface

Metal-to-metal contact with hard jaws can leave scratches or marks on your part. This is a big problem if the surface must stay clean or shiny. Soft jaws stop this by gently holding the part. They dont press too hard or leave marks.

Real Example: A company that makes aluminum parts saw a 15% drop in post-machining polishing time after using soft jaws. That saved them time and money.

Consistent Part Geometry

With soft jaws, the same setup can be used for many parts. This means each part comes out the same, with no changes in shape or surface. You can trust that your product will meet quality checks every time.

This also means less scrap, less rework, and more customer satisfaction.

Actionable Tips for Using Soft Jaws Effectively

To get the best results from lathe soft jaws, follow these simple tips:

1. Measure and Machine Soft Jaws for Each Workpiece

Always take time to measure your part and machine the soft jaws to match it. A good fit means better grip, less vibration, and better surface finish.

2. Use High-Quality Materials

Dont buy the cheapest soft jaws. Use quality aluminum or steel. High-grade materials last longer and perform better. They are less likely to wear out or break during use.

3. Inspect Regularly

Check your soft jaws after every few uses. Look for wear, dents, or damage. If the jaw shape changes even a little, it can hurt accuracy and surface finish.

4. Re-Machine or Re-Index When Needed

If you are making thousands of parts or very critical components, its best to re-machine the soft jaws after a certain number of uses. You can also re-index them in the chuck if needed.

Conclusion

Lathe soft jaws are powerful tools that help you improve machining accuracy and achieve better surface finishes. They hold parts more gently but firmly, reducing distortion and surface damage. They also reduce vibration and allow for the same setup to be used over and over again.

Using soft jaws leads to:

-

Less part movement

-

Fewer defects

-

Better surface quality

-

Lower finishing and polishing time

-

More repeatable results

If you want your machine shop to produce higher-quality parts with fewer reworks, investing in soft jaws is a smart decision. Just remember to use them properly and take care of them.